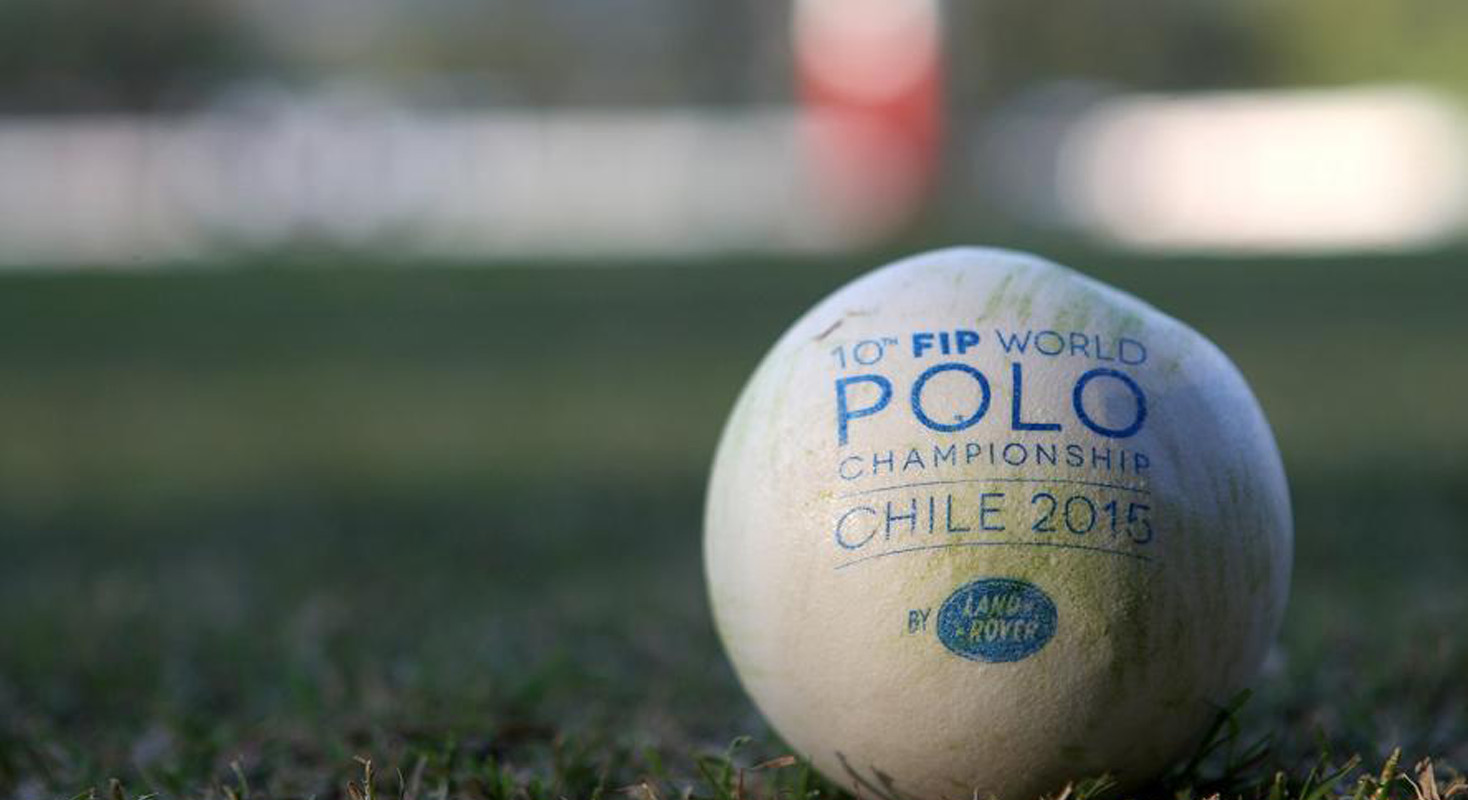

ULTIMATELY IT’S ABOUT HITTING THE BALL, AND IT’S ABOUT BALL HUGGING THE GOAL

A ball sport- played on horses- commonly called Polo.

The modern outdoor polo ball is composed of high-impact plastic. the weight of the ball is four and a half ounces and is three and a half inches in diameter. The evolution of the polo ball has been historic. Initially, the components included bamboo, leather-covered cork, hard rubber, and for many years willow root. Initially, the British used a white-painted leather-covered cricket ball. The regulation outdoor polo ball has dimensions as follows: 3 inches to 3 1⁄2 inches in diameter and weighs 3 1⁄2 ounces to 4 1⁄2 ounces. Balls shall be limited to 3 to 3 ½ inches in diameter and 3 ½ to 4 ½ ounces in weight. The indoor and arena polo ball is usually leather-covered and inflated and is about 4 1⁄2 inches in diameter. It must be not less than 12.5 inches and more than 15 inches in circumference. The weight must be more than 170 grams and not less than 182 grams. In a bounce test from 9 feet on concrete at 70 °F, the rebound shall be a minimum of 54 inches and a maximum of 64 inches at the inflation rate that is specified by the manufacturer. This provides for a hard and lively polo ball. Plastic balls were introduced in the 1970s in the evolution of polo balls. They are less prone to breakage and much cheaper. Since 1890, the US Polo Association has governed the equestrian team sport of polo played in the United States and neighboring countries. Over time, the composition of the ball has changed.

FROM BAMBOO TO WOOD AND THEN FINALLY SETTLING TO PLASTIC

Ranjit Mal from Deulpur, West Bengal takes pride in calling himself the last man on earth who can make polo balls from a bamboo strip. India has been the producer of the best-known bamboo balls because of the availability hub of bamboo is the lush greenery and the ponds in the village of West Bengal, Deulpur. The balls were exported to the United Kingdom, the United States, and other countries. Previously the manufacturers of the bamboo ball were forced to work several hours at stretch to meet the high demands and the deadlines of the polo players. Throughout the evolution of the polo ball, the process of making the ball has remained the same, it has been a labor-intensive industry and the entire work is done manually. Mal says: “The massive, solid bamboo rhizome, which is the underground part of the stem, is from tropical bamboo species such as Guadua. The giant bamboo rhizomes are dug deep as they are all interconnected with each other. The rhizomes are then soaked inside a pond for 18-20 days continuously. The balls carved out of these jads (roots) should be exactly three-and-a-half inches in diameter and should weigh 0.15 kg or else they are rejected by the players. The balls are done after a double coat of white Asian wall paint.”

The invention of this cradle of wooden polo balls has virtually left with nothing to take its rich legacy forward. The risk of manufacturing wooden balls for the high demanding polo game eventually paid off when two British soldiers, Captain Robert Stewart and Joe Sherer, established the Calcutta Polo Club in 1862. The demand for polo balls integrated with the formation of the Indian Polo Association in 1892. The country used to boast 100 clubs by 1900. Bamboo balls were supplied by Deulpur craftsmen across the country.

Subsequently, Baug Brothers were set up by Satish Chandra Baug and Jugal Kishore Baug in 1950: “They decided and became a major exporter of wooden balls in a few years as the balls were preferred over the bamboo balls, for they produced a whistling sound due to friction with the air that helped the player to hear the ball coming and thus avoid getting hit by it.” The evolution of polo balls brought huge profits to the manufacturers and Deulpur boasted four major manufacturers and exporters of polo balls, including Baug Brothers, Kolley Das, Baug Company, and Hazra & Sons. During the 1970s and 1980s, the balls demand grew instinctively in the United States, England, Australia, Nigeria, and also in the Indian states of Jaipur, Manipur, and Kolkata where the game was mostly played,” says Baug.

In 1990 fiberglass polo balls from Argentina were introduced. But fiberglass polo balls also known as Argentinean balls, have dealt a deadly blow to the bamboo polo ball industry all these years. Even though Argentinian balls are far more expensive than wooden ones, they are preferred because of their uniform weight and their durability, virtually decimating the wood ball industry. Usually, around 2,000 bamboo balls are required for a tournament as the wood cracks after being hit hard regularly. The balls have to be discarded at regular intervals owing to their disruption. The fiber-glass balls don’t come with such a disadvantage and 500 balls are enough for the tournament in one go.

EXPERIENCE DIFFERENT BALLS WITH DIFFERENT POLO GAMES

Bicycle Polo:

The ball equipment required for bicycle polo is similar to that of a traditional polo ball. The arena polo ball will be used in the following game. The ball shall be not less than 12.5″ or more than 15″ in circumference and more than 170 grams or more than 182 grams in weight to have a perfect hit. In a bounce test from 9′ on concrete at 70ºF, the rebound should be more than 54″ and a maximum of 64″ at the inflation rate specified by the manufacturer.

Elephant Polo:

The game uses the standard size and dimensions of a regular polo ball. The game differs in its name for the sake it is played on an elephant’s back. The game is exactly played like polo, with similar rules and regulations to the sport.

Canoe Polo:

Canoe polo follows certain specifications for the ball that were inaugurated in section 38 of the International Canoe Polo Federation. The ball should be round and shall have an air chamber with a self-closing valve. It should be waterproof, without external strapping or any covering of grease or similar substance. The weight of the ball should be more than four hundred grams and not more than four hundred and fifty grams. For games played by Men, Under-21 Men, and Master Men, the circumference of the ball should be more than sixty-eight and not more than seventy-one centimeters, and its pressure shall be 90-97 kPa For games played by Women, Under-21 Women, and Master Women, the circumference of the ball should be more than sixty-five and not more than sixty-seven centimeters, and its pressure shall be 83-90 kPa

Water Polo:

A water polo ball is a ball used for both, water polo and canoe polo, usually characterized by bright yellow color and ease of grip ability, to allow it to hold with one hand despite its large size. The ball weighs 400-450 grams and is inflated to 90-97 kPa gauge pressure for men and 83-90 kPa for women. Water polo balls mainly come in two sizes: a size 5, intended for use by men, and a size 4, intended for women. Smaller balls are sometimes used by juniors for “mini-polo,” though these miniature balls do not come in standard sizes and are often colored green.

THE TIMES YOU STRUGGLE HITTING THE BALL

No matter how long the player has been in a field, how many years he has played, and how many handicaps he is, the problems in hitting the ball are genuine and most prominent. The major of it is in relating to the distance that a polo player can make the ball travel and the direction and how far the ball ends up going. It’s merely facile to not sustain accuracy and get frustrated unable to hit the ball in your direction, which ends up leading the player towards a psychological barrier in improving the game and making underconfident.

Sarah Wiseman, Handicap 7( 2 in mid polo), a polo player from the UK states “I always take my hand swing back to basics when I’m having a bad game. By simplifying everything about your swing, you can mend all game matter of woes.”

Aid your game back in line with these checkpoints:

Speed: Hitting a ball faster will never get your ball to go any further. Regardless of the speed of your horse, the speed of your swing should be the same. If You rush your swing instantaneously, you finish by leading with your hand. And doing this you will end up topping the ball and lifting your head. Apply this technique if you have to hit the ball with less power.

Force: You miss the small notes while keeping details in your bag. The head of the mallet should meet the ball at the same time as your hand. This ensures that the stick is at its longest when connecting with the ball, allowing you to connect under the ball and enabling it to travel further in the game. If your hand is beating the mallet head to the ball, you are swinging either too fast or enforcing it. This might result in tapping the ball with a lack of distance and hence failure. The problem starts with how to hit the ball and then travels up to your head.

Timing and positioning: this will affect your swing immensely. Miss-hitting the ball frequently might result in failures. Firstly you will be unable to rotate, you will rush your swing to avoid hitting your horse and lift your head, as you will have to almost be vertical in the saddle to try and connect with the ball.

If the ball gets damaged such that it is unplayable by being chipped or broken, or trodden into the ground the Umpire shall stop the game. A chipped, broken, buried, or unplayable ball should be at the sole discretion of the Umpire. In case the ball is minorly chipped or broken, the Umpire should not stop the game until it is in such a position that neither team is favored. In the case of a broken ball, the largest piece shall be played.